Vibration bentlynevada learn and understand about vibration monitoring system and overview and vibration monitoring working principle.

Vibration monitoring system principle.

Displacement sensors measure changes in distance between a machine s rotating element and its stationary housing frame.

Displacement sensors come in the form of a probe that threads into a hole drilled and tapped in the machine s frame just above the surface of a rotating shaft.

Vibration monitoring system for optimum performance of the machine it is very necessary that parameter like vibration speed position bearing temperature pressure and lubricating oil conditions of machine must be monitored continuously so that any change in any parameter could be rectified without any time lag to avoid any severe damage.

Previous studies have mainly concentrated on the vibration mitigation effect of the inerter system without an explicit consideration or utilization of the damping enhancement mechanism.

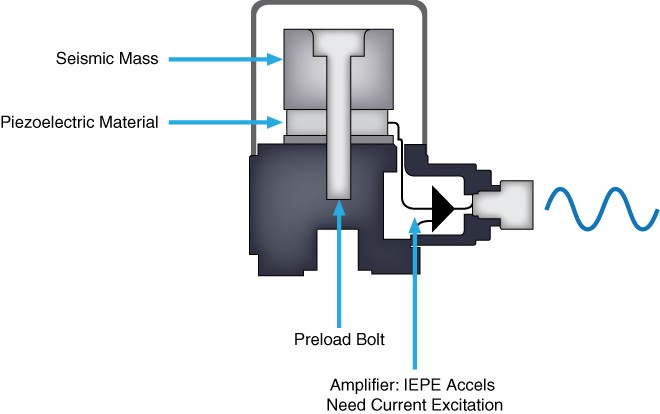

Sensors used to measure vibration come in three basic types.

Find the fault in the machines.

Vibration monitoring can be defined as the monitoring of the rotary equipment pumps compressors turbines fans etc using a set of tools to find out equipment health continuously or at a predetermined interval that can develop vibration or equipment malfunction in the system.

Drawing on the author s more than two decades of experience with machinery condition monitoring and consulting for industries in india and abroad machinery condition monitoring.

Basic concept of vibration monitoring system.

In this study the theoretical essence of the damping enhancement effect is discovered and a universal design principle is proposed for an inerter system.

View more of instrum.